AUTOMATION PDATE

Protecting electromechanical interfaces against liquids is one of the basic requirements for industrial electronics in automation and process technology. However, the term ‚waterproof‘ is a matter of interpretation. Depending on the respective application, for electrical connection technology, different degrees of resistance to liquids are required.

Waterproof: the colloquial term suggests the total resistance of an object to the effects of humidity – for example in the form of fog or rain – and to immersion in liquids. However, it is already known from everyday experience that there is usually only relative protection, for example of a watch, a camera or a smartphone, whose specifications only permit submersion to a limited depth or a maximum hydrostatic pressure. For users of industrial electrical connectivity products, it is obvious to transfer this experience to the application scenarios for connectors, for example in process technology. Protection of the interfaces against liquids is an essential requirement here, both from a functional and a safety point of view.

In order to ensure the tightness of the overall electromechanical system, connectors are of particular importance in industrial electronics. On the one hand, they must be able to be plugged and unplugged several times; on the other hand, depending on the particular application, the connection must reliably prevent the ingress of liquid media when plugged in.

The degree of resistance required – and thus the correct interpretation of the attribute ‘waterproof’ – is inseparably linked to the circumstances of the application in question: While connectors are not in direct contact with humidity in many automation tasks, there are special applications where they are exposed to splash water or even have to withstand temporary submersion. Particularly in hygienically demanding environments, connectors may be treated under high pressure for cleaning purposes. In such cases, special design considerations are essential to ensure reliable signal and power transmission.

The degree of resistance to humidity and liquids is indicated in the product data sheets of the connector manufacturers. The relevant technical specification refers to the so-called protection degree; it determines under which environmental influences – physical touch as well as ingress of particles and water – the respective

connector can be used. In accordance with the DIN EN 60529 and ISO 20653 standards, the protection degree is specified by means of an IP code (International Protection), which for connectors is generally valid only when these are mated. The above examples therefore correspond to the protection degrees IP67 – protection against temporary immersion – and IP68/69K – protection against permanent immersion or exposure to high pressure. Since the standards do not define criteria such as ‘temporary’ or ‘permanent’ in a clear and mandatory manner, it is advisable for manufacturers to provide more precise information in practice.

In practice, insufficient knowledge of DIN EN 60529 or ISO 20653 often results in the misleading assumption a high number in the IP code necessarily means better protection. It is therefore important to know that the first digit of the code refers to the ingress of solid particles, such as dust, while the second digit indicates protection against humidity and water. Thus, a product rated IP64 cannot be considered ‘better protected‘ in general compared to an IP55 product. The former may be more exposed to particles, i.e. it is dustproof. However, it can only withstand splashing water, while the second can be exposed to jet water from any angle.

The two digits for particles and humidity/water can be followed by code letters in the third and fourth positions to indicate the protection degree more precisely. For example, a K (as in IP69K) stands for road vehicle equipment; a B for access to hazardous active parts with a finger.

It is important to emphasize that the IP protection degree refers to the protection of equipment and its components only. It does not make any statement about the protection of persons who interact with this equipment. Measures for the safety of users are defined in the so-called protection class, which is not the subject of this article.

In addition to electrical parameters such as rated current and voltage, surge voltage or contact resistance, installation-relevant parameters such as integration density and degree of miniaturization – and consequently the design

of a connector – are general selection criteria. Beyond this, however, it is necessary to evaluate the special features of the respective application environment. Is the interface exposed to mechanical loads such as shocks or vibrations? Are precautions to be taken against the influences of adjacent high-frequency electronic assemblies, against the risk of fire or explosion? Or does a connection that has to be mated and unmated frequently require special design considerations in order to endure many mating cycles? The answers to these and similar questions lead the user to product features such as locking system, electromagnetic shielding and contact materials, which necessarily influence the purchase decision.

The fact that connectors must – in an initially undefined manner – withstand the ingress of particles and humidity or liquids is a standard requirement in the industry. But as explained above, the necessary protection degree depends on the details of the application. As these range from interfaces in measurement and control in factory automation, through the Food & Beverage industry, to clinical use of medical instrumentation, the requirements for ‘waterproof’ connectors can vary considerably. Especially in the latter two areas, the products are exposed to a particular humidity load resulting from the cleaning and sterilization processes required here.

All M12 connectors from binder are resistant to moisture and water in accordance with IP67 standards, and many are also resistant to IP68/69K. Corrosion-resistant variants are equipped with stainless-steel or plastic threaded rings (Figure 1). While IP67 ensures application safety in occasional humidity – without higher requirements – the more resistant products, depending on the protection degree and material, can also withstand weather conditions in outdoor use as well as immersion in greater depths, high-pressure water jets and aggressive cleaning agents.

The IP67 portfolio also includes M12 plugs and sockets that can be assembled. Connection technology with IP67 protection, such as the binder NCC (Not Connected Closed) series 770 (Figure 2), are recommended, for example, for use in handheld terminals, medical equipment and LED lighting assemblies. Equipped with a bayonet lock and designed for more than 5,000 mating cycles, these products are characterized by a special design feature. A spring-loaded plastic cover inside their housing encloses the contacts – when unmated – so that they are safe from accidental touch. They are thus protected against particles and splash water, and are also protected against mechanical impact from the outside.

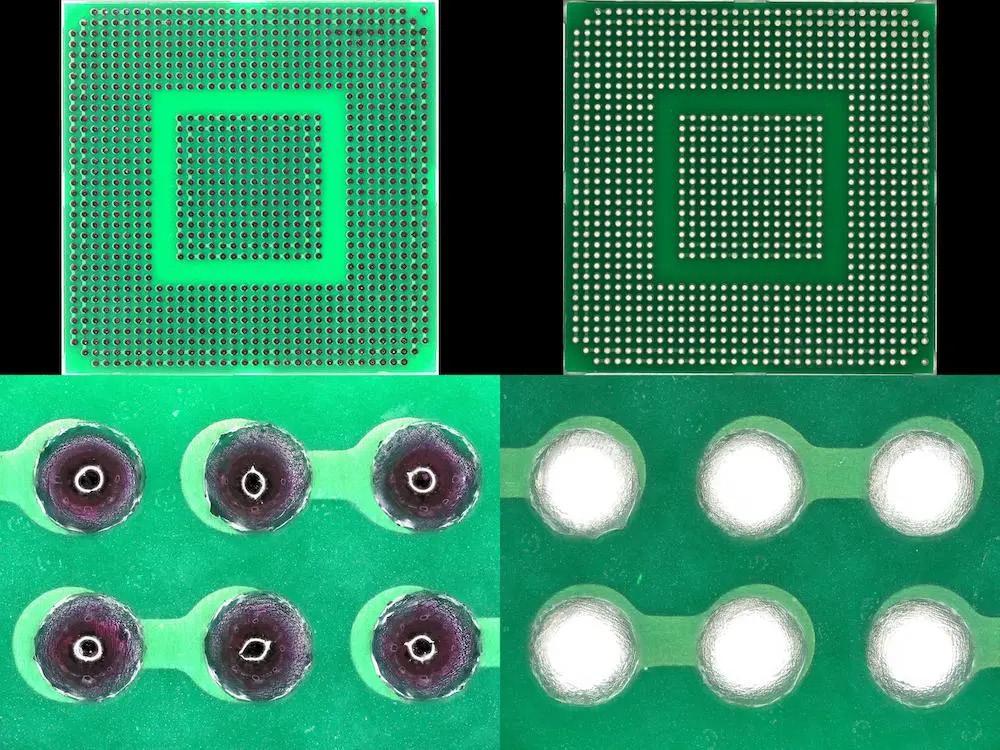

The so-called subminiature and miniature series 620 and 720 – when mated – also meet the IP67 criteria (Figure 3). For this purpose, they are equipped with an O-ring on the female end as well as with a seal in the clamping area. Despite their sensitive snap-in elements, the connectors withstand more than 1,000 mating cycles. They are also suitable for medical equipment; other possible applications include metrology equipment, industrial lighting or the seat heaters in sports stadiums.

All molded cable connectors of the 763 series (Figure 4) featuring signal and sensor cables as well as threaded rings made of media-resistant and temperature-resistant plastic are waterproof to protection degree IP68 when mated. Protection to IP68/IP69K is achieved by the outdoor connectors with bayonet quick locking of the HEC series (Figure 5). Application examples include tunnel lighting for very humid environments, underwater metering probes and supply lines for submersible pumps. HEC connectors are also widely used in agricultural machinery and in portable handheld welders. The outdoor and stainless-steel versions of the 713 series (Figure 6) also comply with protection degree IP68/69K. The outdoor versions are made of plastic suitable for this purpose and are equipped with protective caps that preserve the signal connectors from the effects of weather in outdoor use. The stainless steel products are particularly resistant to aggressive agents.

Figure 1: The M12 design is widely used in the field level of automation, for example for sensor-actuator cabling; field-wireable male and female connectors provide flexibility during installation.

Photo: binder

Figure 2: Not Connected Closed – thanks to a spring-loaded plastic cover, the NCC connectors of the 770 series are protected from particles and splash water even when unplugged. Photo: binder

Figure 3: Miniaturized and waterproof to IP67: The 620 and 720 series with O-ring on the female side and seal in the clamping area.

Photo: binder

Figure 1: The M12 design is widely used in the field level of automation, for example for sensor-actuator cabling; field-wireable male and female connectors provide flexibility during installation.

Photo: binder

Figure 2: Not Connected Closed – thanks to a spring-loaded plastic cover, the NCC connectors of the 770 series are protected from particles and splash water even when unplugged. Photo: binder

Figure 3: Miniaturized and waterproof to IP67: The 620 and 720 series with O-ring on the female side and seal in the clamping area.

Photo: binder

Particular Food & Beverage versions of the binder 763 series and the stainless steel variants of the 713 series are protected to IP69K. The M12 connectors are suitable, for example, to connect sensors that monitor process parameters in bottling plants. In general, they are intended to be installed in machines and systems that are cleaned with high-pressure cleaners and aggressive cleaning agents.

Protecting electromechanical interfaces against the effects of liquids is a fundamental requirement in industry. The degree of resistance required always depends on the specific environmental conditions of the respective application. In the product documentation of the component manufacturers, it is represented by the protection degrees or IP codes. binder offers connection technology in accordance with IP40 to IP68/69K, with a large part of the connector portfolio meeting the requirements of IP67 and above. The binder products are thus recommended, for example, for use in the fields of automation, building, agricultural, food and medical equipment technology.

The circular connector specialist binder from Neckarsulm, Germany, offers waterproof connectors for harsh environmental conditions that have been developed for protection degrees IP67 to IP69K. UV- and temperature-resistant material is used in selected products, and some of the connection technology is suitable for demanding hygiene requirements. In detail, the design has been optimized to prevent dirt deposits on the housings; IP69K connectors can be cleaned with high-pressure jets, special stainless steel variants are resistant to aggressive cleaning agents, and overmolded connectors for the Food & Beverage market segment are also certified according to the specifications of the test service provider Ecolab. A selection of different locking systems and materials is available for various application scenarios – such as M12 threaded rings made of plastic or stainless steel, or bayonet or snap-in mechanisms optimized for applications that require fast and frequent mating. The balance of function and design in product development is worth highlighting. Thanks to special coloring, the connectors meet typical market design specifications, for example for the Food & Beverage segment or for medical technology.

About the author:

David Phillips has been the managing director of binder UK since it was established in 2009. In January 2022

David Phillips was also appointed as international sales director and is now responsible for the nine binder group offices worldwide. An experienced sales and marketing professional of 30 years he’s spent the last 20 years in the connector industry. Prior to binder he was the sales director for an independent distributor. He says “binder is focused on markets which require high-performance, high-quality interconnection solutions”.

www.binder-connector.com

Figure 4: IP68-compliant 763-series cable connectors in different versions. Photo: binder Figure 5: HEC series of outdoor connectors according to IP68/ IP69K. Photo: binder Figure 6: 713 series, IP68 – protective caps keep the contacts safe from the weather in outdoor applications. Photo: binder

ABB Robotics has been selected by Nobia - the leading kitchen specialist in Europe – to supply robotic automation solutions for their new factory in Jönköping, Sweden. By securing the contract, ABB Robotics furthers its expansion into new industry segments, helping to make production more efficient and sustainable.

“ABB’s contribution to Nobia’s new state-of-the-art factory clearly illustrates how we are helping companies unlock flexible automation to transform their business, supporting with unique global industry expertise and innovative, tailormade products,” said Andrea Cassoni, Managing Director, General Industry, ABB Robotics. “Working with Nobia, our robotics solutions will enable fast mass-production of customized kitchens, meeting consumers’ increased demand for tailored and personalized product choices”.

The supply of ABB robots will enable Nobia to achieve its vision for more flexible and more automated manufacturing that’s capable of producing customized products at scale. By taking on the dull, dirty and sometimes dangerous tasks, the range of robots will enable Nobia’s workers to take on safer, more rewarding work. The robots included are IRB 7600, ideal for heavy applications, IRB 4600, a general-purpose robot that increases production capacity and improves productivity, and IRB 6700, the highest-performance robot in the 150–300-kilogram class which, on average, takes about 2.5 tons per day off the shoulders of an employee. The robots will enable the factory to produce customized cabinets with 75-80% higher efficiency (time) in comparison to non-automated processes.

Combining ABB’s technological leadership in automation with Nobia’s segment insights and knowledge of their customers’ needs, the relationship will lead to more flexible and

digitalized manufacturing processes. Together, the companies strengthen the competence development within automation for the region around Jönköping. In the local area, ABB Robotics will support and educate Nobia’s existing and future employees as well as students at Jönköping University and neighboring Linköping University. The training will be held in ABB Robotics’ recently opened training center in Jönköping.

“We are very excited about this partnership with ABB. We are building a future-proof, high-capacity factory that will support our leading position. It is a real game changer for the whole industry. The factory will manufacture customized, madeto-order kitchens at the highest speed and at the same time highest possible quality. The unique combination of technique solutions combined with our expertise will enable us to offer kitchens with leading design, and sustainability performance to customers in the Nordic region. To achieve this we will utilize ABB’s market leading technology for highly automated and flexible processes, and extensive logistics consolidation,” said Jon Sintorn, CEO, Nobia.

The region around Jönköping is characterized by extensive know-how and expertise in manufacturing, with ABB Robotics further enhancing this through its work with Nobia. The factory will be fully operational in the course of 2024, to become one of Europe’s most modern kitchen factories.

Faster time-to-market, more efficient engineering, more functionality, and higher quality – these are the benefits of a digital twin for machine and system builders. Digital twins can be used in many places in engineering, depending on the application.

Machine and system builders will demand digital twins so that they can develop their machines and systems faster and make fewer mistakes during the process,” explains Gerhard Borho, Member of the Management Board Digitalisation at Festo. Step-by-step, the principle of ‘digital first’ continues to advance. Components and machines are developed virtually as much as possible before the hardware is produced; this also applies to testing and system integration. Similar developments can be seen in factory planning.

Shorter development times require further simultaneous engineering by the machine builders. Digital twins, therefore, need to replicate the capabilities of the components, if necessary, down to the physical behaviour. This significantly shortens customers’ project timelines and increases productivity. Even before a machine developer has assembled the machine hardware, they can simulate it, test it, and make adjustments. For example, they can design and program optimum, efficient handling systems using the virtual model. That is how errors can be detected and corrected at an early

stage, which significantly contributes to efficient and stable operation later.

Digital twins of automation components are much more than just 3D models that move virtually. They are digital representations that provide all kinds of information about the components, including a clear description of their capabilities, the documentation, the behaviour – e.g., simulation of their kinematics and kinetics – and the communication with them, including the role they play in the machine.

The Industry 4.0 machine architecture is based entirely on digital twins. Thanks to their standardised communication interfaces, they make life easier for our customers throughout virtually the entire lifecycle of a machine: from virtual commissioning and control of the machine to data acquisition and the resulting value-added services such as maintenance or diagnostics. Behavioural models of pneumatic functions were used to commission virtually the labelling machine mentioned earlier. The reduced need for searching in catalogues, on support portals or for preparing machine documentation provides further time savings.

Until now, there was a multitude of data for each automation component in different formats such as CAD, PDF or even paper manuals. Data management was, therefore, cumbersome and difficult to access throughout the entire lifecycle of an automation product. This lack of digital continuity also made it difficult to fully network all objects. Festo is therefore working on seamless and consistent communication technology such as OPC-UA. Ultimately, the administration shell is used as a central source of information to utilise digital twins throughout a component’s service life.

Digital twins make things easier right from the planning stage and the preparation of concrete proposals.

“Intelligent algorithms can be used to design and configure optimum and, at the same time, energy-efficient components,” adds the Member of the Management Board Digitalisation at Festo.

A virtual model allows the developer to test whether the slide can be moved, for example, and view the process data from the displacement encoder or the signal from the end position sensors. If the developer wants to create control sequences for the machine, they can easily be created using the components’ functions such as extend, rotate, or grip.

Other value-added services can also be implemented on the basis of digital twins. The condition monitoring function generates a message when, for example, operating components are approaching the end of their service life. The machine’s digital twin could then automatically order spare parts. If at that point there are newer models for the components being replaced, the customer can use the virtual environment to first test how the new components interact before ordering them.

Condition monitoring can also be used in conjunction with the simulation models of the digital twins to create predictive maintenance plans. Furthermore, customers can use the digital twins to develop and test subsequent changes, optimisations, or reconfigurations on the virtual model before these are implemented on the machine, which speeds up the process.

Together with other component suppliers, Festo has incorporated the digital twins of its electric and pneumatic automation products into a use case that gives machine and system builders the opportunity to discover the advantages of the digital twins live in the engineering tools from Siemens.

www.festo.com/digitalisation

www.festo.com/didactic

• 80% of stand space already sold

• Powell Electronics confirms headline sponsorship alongside Wurth Elektronik and Solid State Supplies

• Dassault Systemes returns as gold lounge sponsor and sponsor for The Engineer conference and Eureka conference

• Mouser Electronics confirm lanyard sponsorship

Previous exhibitor, Adam Miller, Field Sales Engineer from Ineltek commented on last year’s show:

“The resurgent Engineering Design Show exceeded expectations. Ineltek’s stand had a steady stream of relevant visitors from a variety of technology businesses. The two days flew by; we never reached the point where we had to kill time visiting other stands. EDS is back with a bang!”

The Engineering Design Show (EDS) returns to The Coventry Building Society Arena on the 11th – 12th of October 2023. This two day exhibition has been curated specifically for design engineers and will bring together over 200 suppliers, thousands of products and all the latest industry innovations.

The exhibition is set to be jam-packed with hundreds of stands already booked. Exhibitors include Moons Industries, Technosoft, Telsonic, Smallfry, McLennan, Thermal Vision Research, Etal, Quickparts, Hoover, The Robot Studio and Reliance Precision and many more!

Alongside the exhibition, visitors can attend 30+ hours of free conference sessions and workshops, bringing together the biggest names in the industry. There will also be ample space for one-toone meetings and time to network, with the dedicated gold lounge, sponsored by Dassault Systemes, a central café and a drinks reception held at the end of the first day.

EDS has everything to support UK design engineers in 2023. Register your interest here to be the first to find out when registration opens and to keep abreast of all the latest show news: https://www.engineeringdesignshow.co.uk/register-interest

Exhibiting at EDS is a fantastic way to maximise your organisation’s exposure to the UK’s design engineering community. For more information, visit engineeringdesignshow.co.uk and find out how we can tailor your package to meet your exact requirements.

Hundreds of exhibitors are already confirmed for this year’s Engineering

Vapour degreasing is the simplest but most effective industrial solvent cleaning process which, until recently, has been subject to little change since it was first invented in the early part of the 20th century. This is a very mature chemical technology, but legislation changes in recent years has impacted the industry significantly.

Chlorinated hydrocarbons have historically been the solvents of choice for vapour degreasingcompatible with most materials, stable in use, producing a non-flammable saturated vapour heavier than air at a temperature greater than ambient. Traditional solvents such as trichloroethylene exhibited all these characteristics but concerns about its carcinogenic properties and the danger to operators by exposure, led to a continuing search for a safer alternative. 1,1,1 trichloroethane based formulations became popular in the last century as a safer replacement. Although safer for users, it proved to be depleting the Ozone Layer and was subsequently banned. N-Propyl bromide (nPB) based formulations became popular in the last part of the century as a safer replacement, but this was later put in Annex 14 of REACH by the EU and can no longer be used as a vapour degreasing solvent in Europe. Countries around the world are now setting increasingly stringent environmental legislation to control emissions of Ozone Depleting and Global Warming industrial cleaning solvents. This has led to new chemical formulations being developed for industry.

EnviroTech Europe Ltd have been supplying vapour degreasing solvent formulations for over 20 years, constantly responding to regulatory requirements for environmental and safety laws and the need for improved standards. Staff and distributors are highly trained to work with customers to advise on the use of industrial cleaning solvents, helping them to navigate through legislative changes and ensure their vapour degreasing and cleaning solutions remain within regulatory boundaries.

Customers may have recently read in the industry press about another major industrial supplier ceasing production of their range of fluorocarbon containing metal degreasing and vapour degreasing solvents. They may be concerned that other major suppliers will follow suit. Envirotech Europe would like to assure the industry of its intention to continue the manufacture of its ProSolv® range of metal cleaning and vapour degreasing solvents for the foreseeable future.

Zero Ozone Depletion Potential (ODP) and very low Global Warming Potential (GWP) solvent blend for high performance vapour degreasing

ProSolv®5408e ticks all the boxes with the perfect profile for a vapour degreasing solvent, developed by EnviroTech Europe Ltd for precision parts cleaning or cleaning automated machinery at strip down.

ProSolv®5408e offers improved cleaning at a lower cost, without compromising quality. Substitution is simple with little or no changes to equipment or control settings needed. A non-flammable stable azeotrope needing no testing for acid acceptance or stabilising additives, easy to use and maintain and safer for the workplace.

ProSolv®5408e is extremely effective for precision cleaning in high-tech industries such as aerospace, aviation, electronics and medical device cleaning. It can be used in most solvent cleaning systems, one tank vapour degreasing or multi tank immersion / vapour tank systems using ultrasonics or flush cleaning for complex mechanical and electronic components with blind holes and channels and close mounted electronics or for removing grinding and buffing soils on surfaces. Exceptionally low surface tension to penetrate micron sized holes and close contact surfaces.

ProSolv®5408e is highly effective when used with ultrasonics and can usually be used in existing degreasers or dip tanks. Ideal for precision cleaning and degreasing of electronics, metals and glass. It can be used to remove adhesives, fluxes, pastes, buffing compounds, greases, silicone oils, particulates, resins, waxes and other oils and soils. Soft on the environment, low solvent losses, reduced costs, sustainable and secure for the future.

• Fast precision cleaning, short cycle times. Stable with no additives, no testing required

• Alternative to Methylene Chloride, Perchloroethylene and High ODP/ GWP Fluorocarbons

• Excellent choice to replace flammable solvents such as MEK, Acetone, Isopropyl Alcohol (IPA) or Hydrocarbons

• Established replacement for Trichloroethylene, n-Propyl Bromide (nPB) and other now banned solvents

• Can be used in any vapour degreasing equipment, lower energy consumption and lower maintenance. Compatible with a broad range of substrates

• Improved productivity, parts exit the machine cool, dry, spot-free with no drying required

• High density solution, excellent for ultrasonic cleaning

• Mid-range temperature operation, easier handling, mid-range boiling point, processed components easily handled (48°C)

• Very low surface tension for penetration into the micron level crevices and holes, efficient cleaning in tight to reach places and complex geometries

• Easy process monitoring with minimal effort and minimal waste generation, easy reclamation for reuse

• Minimal non-volatile residue

• High Solvency (KB Value 98) for a variety of contaminants

• Safe for the environment, zero Ozone Depletion Potential (ODP)

• Very low impact on Global Warming (GWP)

• Non-hazardous for transportation

• Non-flammable (No Flash Point)

• Not classified as a carcinogen

ProSolv®5408e vapour degreasing solvent is manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide. Please visit our website www.envirotech-europe.com for information about all our products and further information on ProSolv®5408e.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form

SHENMAO America, Inc. is proud to announce the release of its new SMBF-08 Visible No-Clean BGA Flux. This innovative flux is specifically designed to meet the demands of surface mount technology (SMT) assembly and BGA ball mount processes, offering enhanced visibility and performance.

The key features of the SMBF-08 flux include its visible black coloration, which allows for easy identification and evaluation during the automated optical inspection (AOI) process. Unlike traditional transparent BGA fluxes, the visible black residue of SMBF-08 can be readily detected, providing customers with an efficient way to assess flux application.

In addition to its enhanced visibility, SMBF-08 is halogen-free (ROL0) and fully compliant with RoHS, RoHS 2.0,

and REACH regulations. This ensures its environmental compatibility and adherence to industry standards.

SMBF-08 is a versatile flux suitable for various processes, including stencil printing, dipping, and pin-transfer methods. Its excellent printability, wettability, and solderability make it highly effective for a wide range of IC packages, including system-in-package (SIP), wafer-level-package (WLP), and flip chip technologies.

For more information, please visit www.shenmao.com.

How to guarantee employee protection against machine hazards, maintain productivity and also shield control systems from unauthorised internal or external manipulation? All hot topics in industry, especially in the face of increasing digitisation.

Pilz modular ‘Identification & Access Management’ solutions have this covered, offering functionality such as user authentication, safe operating mode selection, data and network security and access management.

Contact us for your personalised solution!

For data protocols that are difficult to connect, the DataHub Tunnel/Mirror provides easy-to-configure, secure and robust networking. Eliminate the hassles of DCOM, detect network breaks quickly and recover from them smoothly. Access your remote data, not your plant systems. Connect and share data among locations with no DCOM or Windows security issues.

The DataHub Tunnel/Mirror goes beyond the basics, letting you integrate your data without exposing your network. Simply better networking.

You can take a big step towards compliance with the NIS 2 Directive by securing access to your process data.

You may have heard about the NIS 2 Directive. With the growth of Industry 4.0 and digital transformation, more companies need access to their process data. At the same time, cyber attacks on industrial systems are at an all-time high. So the EU has issued a tough new policy--the NIS 2 Directive--which takes effect next year.

Among the mandates, NIS 2 requires “a level of security of network and information systems appropriate to the risks posed.” In practical terms this translates into securing access to process data from corporate systems by segregating OT (operations) and IT networks, using a DMZ.

Skkynet provides a way to do this. DataHub tunnel/mirroring seamlessly passes OT data across a DMZ-enabled connection to an IT network. Most industrial protocols require opening a firewall to access the data, but the patented DataHub architecture keeps all inbound firewall ports closed on both the control and corporate sides, while still allowing real-time, two-way data communication through the DMZ.

Unlike MQTT, which cannot reliably daisy-chain connections across a DMZ, DataHub tunnel/ mirroring maintains a complete copy of the data and connection status from the source to final destination. It provides accurate indicators of data reliability at each point in the path.

And unlike OPC UA, DataHub tunnel/mirroring keeps all inbound firewall ports closed on the OT side, while still accessing the data. It faithfully replicates any or all of the full data set from source to user, maintaining the namespace.

NIS 2 takes effect next year, but you can secure your system now. Keep your OT and IT networks segregated with a DMZ, and pass the data securely between them using DataHub tunnel/mirroring

From the manufacture of numerical control lathes, to automation for short and long series by Gantry Loader. CMZ, a machine tools manufacturer since 1945, has decided to extend its product portfolio and offer 100% customised automation solutions with its Gantry Loader range.

With a clear commitment to European production, the company manufactures almost all the parts for its products in its own factories.

The lack of skilled labour means that companies need real automation solutions that enable them to carry out processes that are 100% automated. What they are looking for are ways to optimise their processes to reduce cycle times, and increase the efficiency and quality of their products. Moreover, the fact that the above-mentioned need for workshop personnel is a latent reality, makes the Gantry Loader one of the most appropriate solutions.

Gantry Loader solutions can be used to automate production processes and reduce downtimes for loading and unloading. This solution is especially useful in the production of both short and long series. Putting the machine to work in automatic mode leaves you free to deal with the other needs of the workshop while the Gantry Loader works to load and unload the parts independently and unaided.

CMZ offers a comprehensive range of Gantry Robots which are easy to prepare and fully customisable. Its slogan is “infinite automation solutions”, and that is because its gantry loaders are highly configurable. Thanks to its highly qualified human team, CMZ is able to study customers’ needs and provide the most suitable turn-key solution.

Its wide range covers an entire category of parts, from the smallest parts to ones weighing 50kg. The ability to load both shafts and flanges means the Robot is equipped with the most appropriate wrist and Workstocker for the parts to be machined. That means the machine can work for 24 hours at a time without the need for human help. The result? A clear increase in productivity and improved profitability.

Compared to anthropomorphic robots, the Gantry Loader has numerous competitive advantages which help to increase the productivity and profitability of the production process. Gantry robots are faster, economic and ergonomic. They are also easier to use, thanks to the conversational programming system designed by CMZ to make changing

parts fast and easy. The programming is very simple because the amount of information users have to introduce has been minimised, making the cycle operate in all cases.

CMZ’s Gantry Loader range can provide a variety of real automation solutions. On the CMZ website you can find actual automation solutions designed for its clients. One of these examples is the automation of Ø57 x 210 mm bolts in a TA-20-YS with Gantry GL20II stacking bolts on Workstocker WS280 with independent 6-bar pallets. For smaller parts, it is possible to automate Ø12 x 75 mm titanium aircraft screws in a TA-15-S with Gantry GL20II using Workstocker WS700 in palletised mode and free-fall ramp. There are infinite possibilities.

100% configurable solutions tailored to the client’s needs in a wide range of Gantry Loaders. On the model GL-6 it is possible to load up to 2 parts weighing 3 kilos each, at a speed in the fast position of 180 m/min. This solution for the smallest parts has Fanuc servomotors and an electric wrist.

The model GL-20 can move up to 2 parts weighing 10 kg each. This model has 3 axes (standard Y axis), rack and pinion transmission and servo-pneumatic wrist. Finally, the GL-100 is ideal for larger size parts, because it can move up to two 50kg parts (a total of 100kg), at a speed in the fast position of 150m/min. With automatic lubrication and servo wrist.

CMZ offers a wide variety of 100% configurable wrists tailored to customer needs. That makes it easy for users to configure a customised automation process. When choosing one of the Series GL wrists, please consider the nature, weight and type of operation to be performed. The range of wrists that CMZ offers can be configured on the basis of the characteristics of the process to be automated.

These are some of the automation solutions CMZ offers. The company, with over 75 years’ experience in the market, has been aware of its customers’ needs and is strongly committed to being the partner in turn-key projects related to automation.

With the new DCB-I drive, KNF is introducing an in-house developed BLDC motor generation for the first time in its history.

This new generation of brushless motors further increases the advantages of KNF diaphragm pumps to the next level in terms of performance, robustness, and durability in combination with the ability to digitally customise the motor parameters. By integrating the motor directly into the pump housing, it was thus possible to implement these features in a more compact size.

The development of our own BLDC motor allowed KNF to specify the individual components so that they are perfectly matched for their use in diaphragm pumps.

Compared to what is usual for other motors, the DCB-I features much larger ball bearings. This significantly improves the robustness and durability, which is reflected in a life expectancy of >20’000h. Furthermore, the unique design creates not only a visually appealing look, but also technical advantages. The cooling fins on the aluminium motor cover also improves heat management, especially when the motor is permanently under heavy load.

The development and manufacture of this new generation of motors is the outcome of a cooperation between KNF and a leading motor manufacturer.

As a result, not only is the motor more powerful (in relation to its size), but the development of its electronics makes it possible to use additional functionalities. As a result, this allows total control over the motor to fully exploit the potential of KNF pumps.

KNF offers the DCB-I for the following pump types:

Gas Pumps

• NMP830

• NMP830 HP

• NMP850

• NMP830 HP

Liquid Pumps

• NF30

• NF60

• FP70

KNF develops, produces and distributes high-quality diaphragm pumps and systems for neutral and aggressive gases and liquids.

For more information please click here

VARIO-X is the decisive step towards the future! Agile manufacturing, sustainability or Industry 4.0 – thanks to 100 percent automation without control cabinets. Modular, flexible and future-proof, Vario-X brings your machines and systems into the future with decentralized installation technology. future. It‘s that simple.

SIMPLY DONE NOW! www.vario-x.com/uk